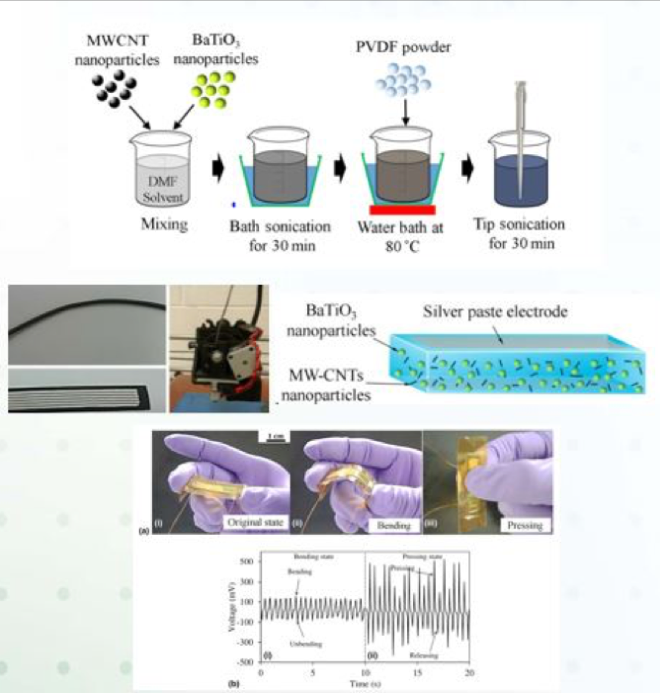

Piezoelectric materials have long been investigated due to their unique characteristic of converting mechanical stress into electrical charges or vice versa. However they are fragile, difficult to fabricate, and requires post processing. One way to alleviate the drawback is to use 3D printing with in-situ poling to fabricate piezoelectric materials in large scale and low cost fashion.

Piezoelectric materials have long been investigated due to their unique characteristic of converting mechanical stress into electrical charges or vice versa. However they are fragile, difficult to fabricate, and requires post processing. One way to alleviate the drawback is to use 3D printing with in-situ poling to fabricate piezoelectric materials in large scale and low cost fashion.

Outcome: Multiwall carbon nanotubes (MWCNTs) are utilized to resolve low coupling coefficient issue by dispersing MWCNTs in poly(vinylidene fluo- ride) matrix to create stress reinforcing network, dispersant, and electron conducting functions for barium titanate (BT) nanoparticles. Various BT and MWCNT percentages of nanocomposite film are fabricated by FDM three-dimensional (3D) printing which can simplify the fabrication process as well as lower cost and design flexibility. Increasing MWCNTs and BT particles gradually increase piezoelectric coefficient. These results provide not only a technique to print piezoelectric nanocomposites but also unique materials combination for sensor application.